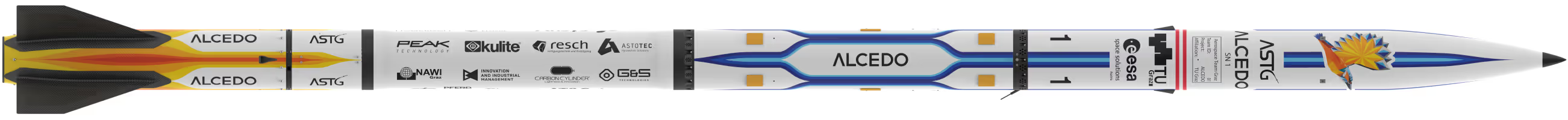

EuRoC 2024 Competition Rocket 🥈

Being the successor of HALCYON, it is our second hybrid rocket and was designed to compete in the H9 category (SRAD hybrid 9 km) at the European Rocketry Challenge 2024.

Building on our knowledge, ALCEDO features significant improvements across all subsystems. The rocket managed an impressive 2nd place at EuRoC 2024. In addition to this achievement, ALCEDO earned the Design Award, Technical Award, and the prestigious H9 Flight Award.

Despite the difficult wind conditions at EuRoC 2024, we managed to have a flawless performance of our adapted parachute system.

The launch vehicle closely resembles last year’s HALCYON, with a 35cm increase in length and an additional 10kg in weight, resulting in a total length of 3.91m and a launch weight of 42.3kg.

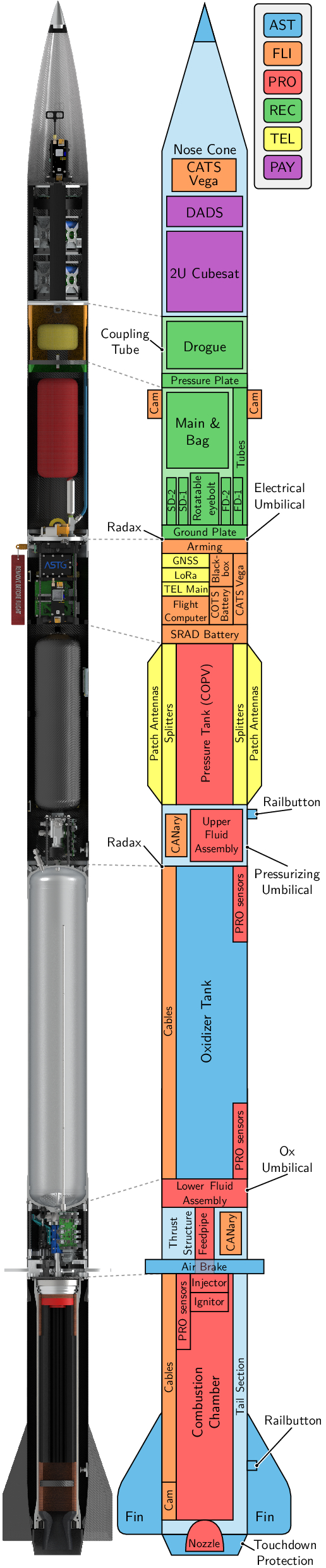

The payload consists of two CubeSats and the DADS payload. This payload is for project APEX, demonstrating an attitude determination system for a future REXUS flight.

The second CubeSat is provided by high school students, fostering the next generation of rocketeers.

The third CubeSat from ASTG features a rotation-stabilized camera to capture parachute deployments.

The recovery section, below the nosecone, houses a dual recovery system with first- and second-stage deployment detection for in-flight feedback.

The avionics stack, mounted similarly to previous years, includes the official tracking computer providing redundancy to our SRAD flightcomputer.

The midsection contains the pressurizing tank, fluid assemblies, oxidizer tank, and various sensors.

The servo-actuated main valve, burst disk, pressure/temperature sensors, and CANARY are located below the oxidizer tank.

The rocket also features an airbrake with a compact design and the valve bay structure to transfer the thrust of the combustion chamber to the rest of the rocket.

The ignitor was reiterated to achieve a more reliable ignition of the HTPB fuel grain.

A flexible and replaceable 3D printed touchdown protection prevents damage to the tailcone during touchdown.

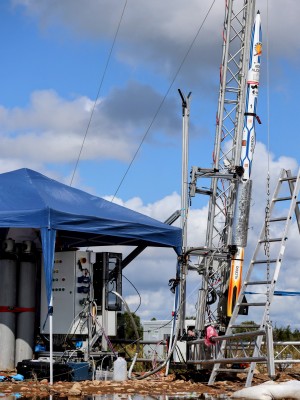

The ground support equipment has been upgraded to perform more reliable and to keep up with the needs of ALCEDO.

The fillingcomputer PCB offers enhanced data sampling, and the umbilical disconnection system has been reiterated for reliable detachment.

Also part of our ground support equipment is our mission control, which features the overall control of the rocket and launch rail equipment, such as the filling station.