EuRoC 2023 Competition Rocket 🥇

HALCYON was our first hybrid rocket project, built to compete in the H3 (SRAD hybrid 3 km) category at the European Rocketry Challenge 2023.

The project combined the proven designs from its predecessor rockets with many newly developed systems.

It was a great success for the team, bringing home not only the H3 Flight Award, but also the EuRoC Award for best overall performance.

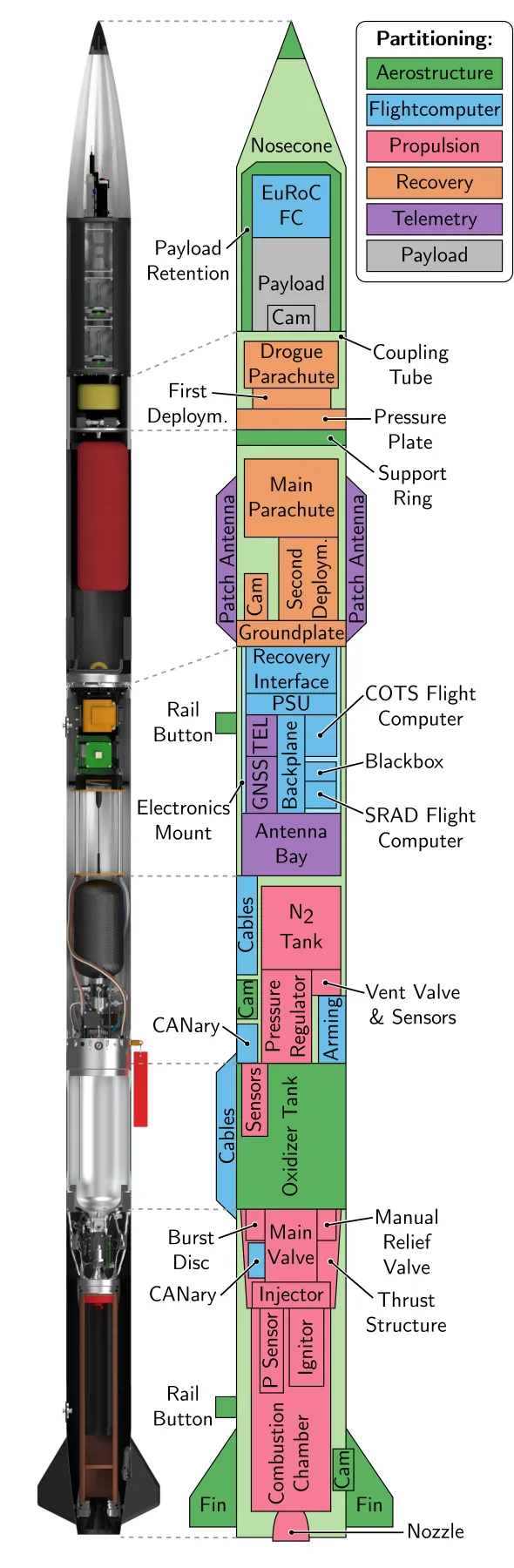

Housed inside the nosecone are the official tracking computer and the payload of three CubeSats, two of which were built by high school students to promote the next generation of rocketry enthusiasts. Additionally, one CubeSat with a stabilized camera was developed as part of a Bachelor thesis.

Continuing down is the dual deployment recovery system with main- and drogue parachute, and telemetry patch antennas attached to the outer hull.

Right below the recovery section, the main electronics bay is mounted. It houses the self-developed flight computer, the redundant recovery electronics, as well as a second telemetry antenna.

Situated further down is the pressurizing system for the rocket's propulsion. Utilizing nitrogen, it ensures near-constant pressure in the 5.5 L nitrous oxide tank during the boost phase.The two tank bulkheads are equipped with integrated fluid ports, sensor mounts, and structural attachment points. Mounted to the lower bulkhead are the servo-actuated main valve, several safety devices, and the aluminium 3D-printed thrust structure.

Last in line comes the combustion chamber, housing the paraffin fuel, capped off by the swirl injector at the top and the graphite nozzle at the bottom.

Enclosing all systems is the airframe, consisting of a series of carbon fibre- and glass fibre-reinforced plastic tubes. Its most recognizable component are the four fins made in lightweight sandwich construction. Positioned between two fins is the downward-facing tail camera, which provides some of the best camera views during a flight.

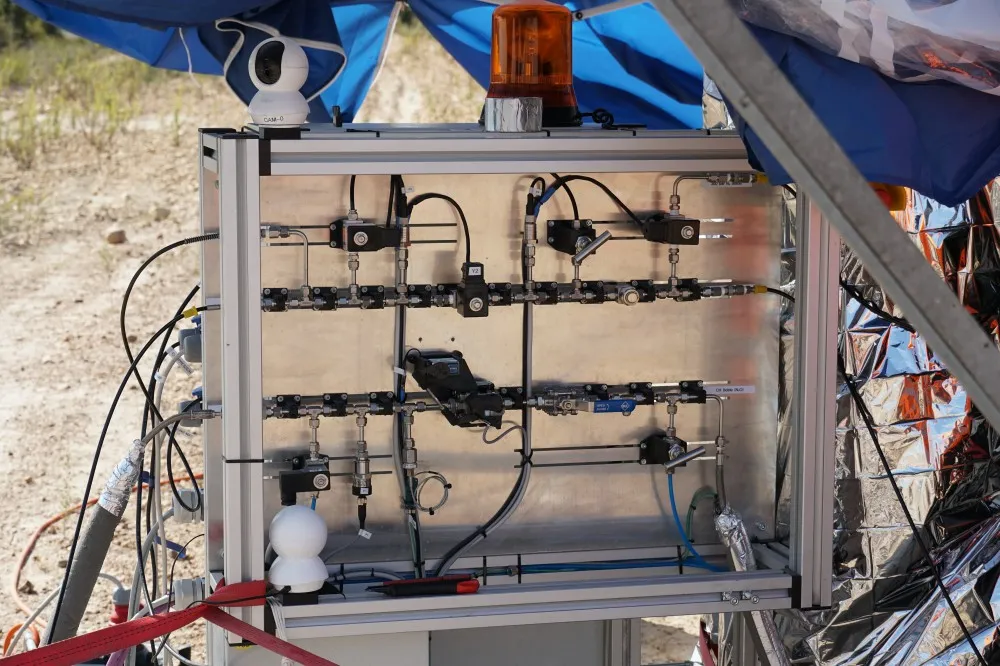

Due to the nature of the hybrid propulsion system, a major effort was put into developing and building the necessary ground support equipment: The filling station, which prepares the liquid N2O and fills it into the rocket, together with the high-pressure N2, and the telemetry ground station which provides the necessary data readouts and actuator controls at a safe distance.

For a complex system like HALCYON to work reliably, an extensive testing campaign was required.

After various individual system tests, e.g. parachute drop tests, multiple horizontal and vertical hot-fire tests, vacuum chamber tests, and telemetry range tests, the testing campaign culminated in a flight test in mid-August 2023 in Manching, Germany.